Custom product development

Solutions for the automotive industry

Hardly any market goes through a similar amount of major technical advances and innovations as the automotive sector. As an automaker or supplier you are committed to accommodating growing customer needs as flexibly and quickly as possible.

That’s where our work begins. We offer custom tailored development solutions for vehicle specific accessories and components. It takes us only a few months to complete such projects. After all, we are keenly aware of how important it is to be able to respond to market developments in the shortest time possible.

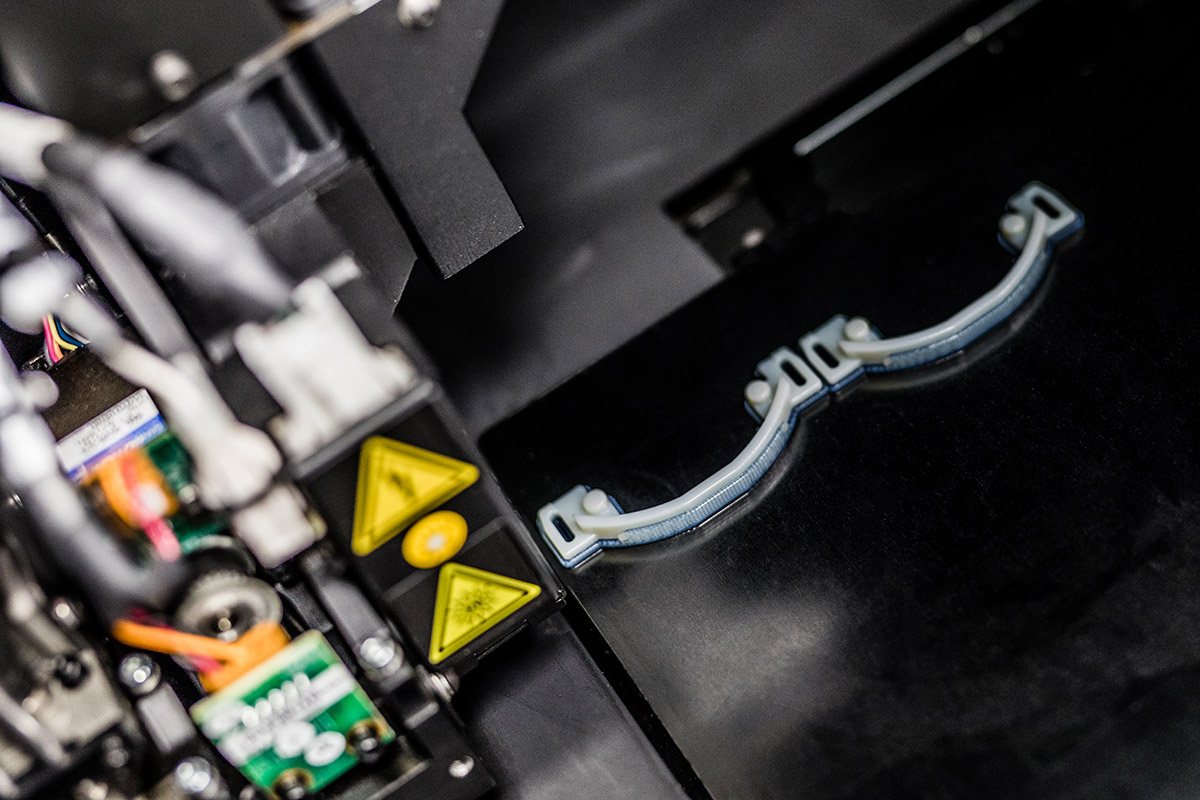

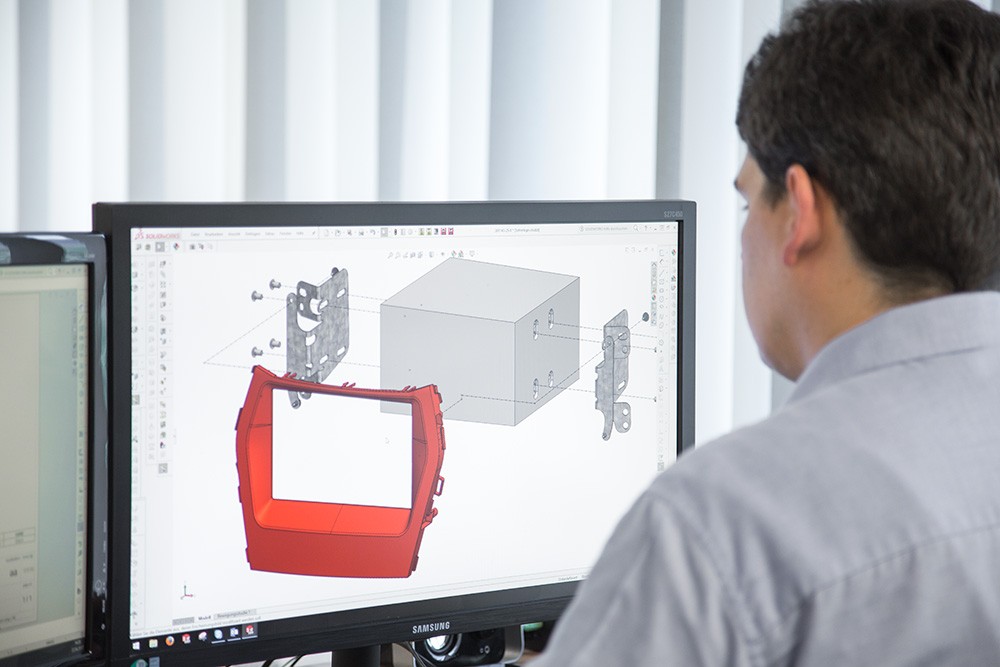

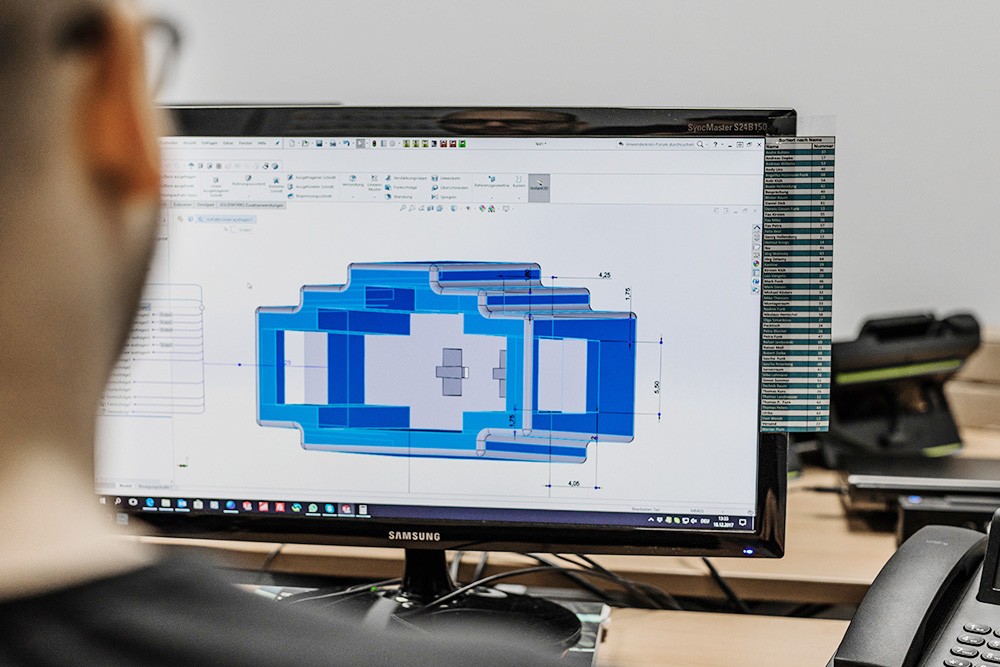

Our perfectly aligned team of engineers and product designers continuously develops and realizes new, innovative technical solutions. We place immense importance on comprehensive and growing expertise and of course deploy state-of-the-art machinery.

Some of the products for which we have developed solutions are:

From idea to series solution in just a few month

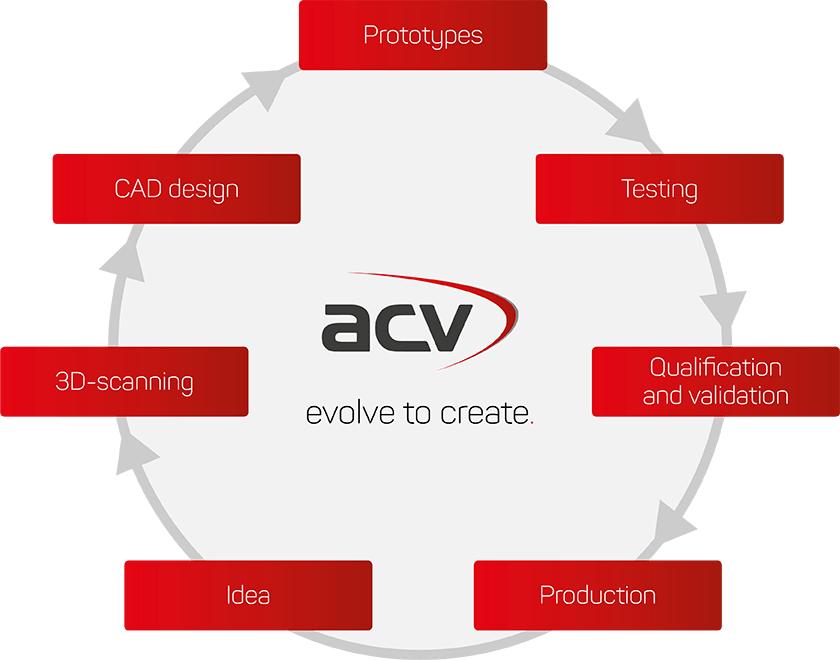

As a system supplier, we take care of all required steps. The process begins with project planning, 3D scanning, design, prototype construction and continues with the verification and validation based on OEM criteria and ends with series production. All quality determining project steps are completed in Germany – engineered in Germany.

Fast, high quality product development

Quality

All quality relevant steps are completed in Germany. Our in-house development department is also located in Erkelenz, Germany.

Speed

We take the process from idea to series solution in just a few months. Thanks to our structured project management, we are able to also expeditiously implement your requests

Flexibility

We respond flexibly to our customer’s and the market’s demands. Joining forces with acv as your partner will enable you to expeditiously respond to market developments.

OEM Standards

Of course we will also be pleased to handle the qualification and validation or homologation in compliance with OEM standards.